In the world of signage and design, cast metal letters are a timeless and elegant choice. These letters, often seen on building facades, monuments, and plaques, have a classic appeal that can add a touch of sophistication to any setting. But have you ever wondered how these beautifully crafted letters are made? In this post, we'll take you through the intricate process of creating cast metal letters.

Design and Typography:

The journey of crafting cast metal letters begins with the design phase. Designers work closely with clients to determine the desired font, size, style, and finish of the letters. The typography is crucial, as it defines the overall look and feel of the finished product. Once the design is approved, it's time to move on to the next step.

Pattern Making:

A pattern maker then creates a master pattern of each letter. This pattern serves as a template for the casting process. The pattern is typically made from wood, plastic, or metal, depending on the size and intricacy of the lettering. Each letter is meticulously crafted to ensure accuracy and consistency.

Sand Casting:

Sand casting is the most common method used to create cast metal letters. Here's how it works:

a. Sand Mold Preparation: A two-part mold is created using fine sand mixed with a binding agent. The pattern is pressed into the sand to create a negative impression of the letter.

b. Molten Metal Pouring: The chosen metal, often aluminum, bronze, or brass, is melted in a furnace. Once it reaches the right temperature, it's carefully poured into the mold. Gravity ensures that the metal fills the letter's cavities.

c. Cooling and Solidification: After pouring, the metal cools and solidifies within the sand mold, taking the shape of the letters.

Removal and Finishing:

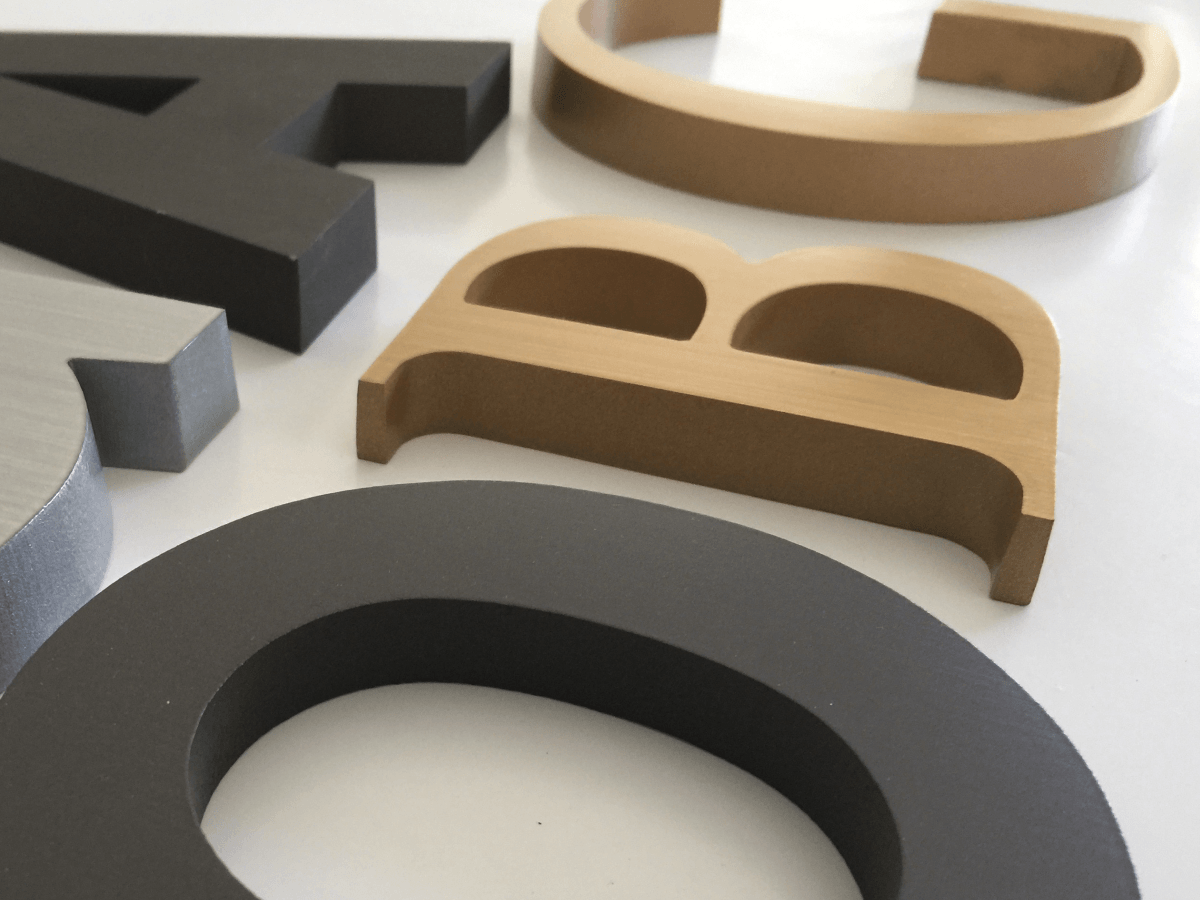

Once the metal has cooled, the sand mold is broken apart, revealing the rough cast metal letters. These letters are then carefully removed, and any excess metal is trimmed away. The surface is cleaned and polished to achieve the desired finish, whether it's a smooth, reflective surface or a textured, aged appearance.

Painting and Patina:

Depending on the design specifications, the cast metal letters may be painted or given a patina finish. Painting allows for customization of colors, while a patina can create an antique or weathered look, adding character and depth to the letters.

The creation of cast metal letters is a labor-intensive process that combines craftsmanship and artistry. From the initial design to the meticulous casting and finishing stages, every step is critical to achieving the desired result. The end product, a set of beautifully crafted cast metal letters, not only communicates information but also adds a touch of elegance and sophistication to the environment in which they are placed. Whether they grace a historic building or a modern storefront, these letters are a testament to the enduring appeal of traditional craftsmanship in a digital age.